Infrared LED Technology White Paper

QUEENDOM Infrared LED Technology White Paper

Industrial-grade optical power and long life solutions

1. Introduction

Infrared (IR) LEDs have become an integral part of many applications around the world, such as surveillance, biometric sensing, industrial automation,

and smart devices. As a professional LED manufacturer, QUEENDOM provides high-performance infrared LED solutions designed to meet international

standards and the needs of customers from all walks of life.

2. Product Overview

QUEENDOM infrared LEDs offer a variety of wavelengths and package types to meet a variety of application scenarios:

2.1 Common wavelengths

850nm: high brightness, slightly visible red light, suitable for security cameras

940nm: invisible to the human eye, suitable for concealed monitoring and proximity sensors

Precise wavelength control: 850nm/940nm dual band, tolerance ±3nm (industry standard ±15nm)

2.2 Package type

SMD (surface mount device): compact size, suitable for high-density circuit board layout

Through hole: rugged mounting, suitable for high-power design

COB (chip on board): efficient concentrated infrared lighting solution

3. Main features

3.1 Features

High radiation intensity: optimized for long-distance detection and imaging

Low thermal resistance: ensures stable performance during continuous operation

Wide viewing angle options: 30°, 60°, 90° and 120° optional

RoHS and REACH compliant: environmentally friendly, suitable for international markets

3.2 Thermal attenuation comparison table

| Temperature conditions | The light decay of this product | Light attenuation of the same level products | Test Standards |

|---|---|---|---|

| 85°C/1000h | <5% | 8%~12% | MIL-STD-883H |

| 125°C/500h | <9% | 15%~20% | AEC-Q102-003 |

3.3 Three major technological breakthroughs

3.3.1. Innovation of quantum well epitaxial structure

Material: AlGaAs/GaAs multilayer heterojunction

Efficiency improvement: Carrier injection efficiency reaches 98% (traditional structure ≤85%)

Compatibility description: Adapt to TDK IR series lens curvature (R2.5mm±0.2)

3.3.2. Copper pillar bump packaging technology

Thermal resistance: 8°C/W (traditional wire bonding packaging ≥15°C/W)

Vibration resistance: Passed 5Grms vibration test (refer to TDK technical document IRD30-5.2)

3.3.3. Military-grade anti-sulfurization process

Coating: Nano gold electrode + nitrogen seal

3.3.4. Environment

Extreme environment adaptation: -40°C to +125°C continuous operation, wet heat cycle passed JESD22-A104-B

Test results:

3.3.5 No sulfurized black spots for 1000 hours in 85°C/85%RH environment

Salt spray test passed IEC 60068-2-11 Lv4

4. Application scenarios

Application areas: Recommended wavelength characteristics

Security monitoring 850nm / 940nm long distance, high infrared output

Face recognition: 940nm, eye-safe, no visible light

Gesture control, 940nm fast response, low power consumption

Infrared communication 850nm high-speed modulation

Smart home devices 940nm compact, low heat generation

Industrial automation 850nm reliable performance in harsh environments

5. Future Outlook

QUEENDOM is actively investing in the next generation of infrared LED technology: miniaturized high-power infrared chips, integrated driver LED modules,

AI-enhanced infrared sensing for edge devices

6. Summary

QUEENDOM infrared LEDs are designed to provide reliability, efficiency and flexibility to customers around the world. Whether you are developing smart consumer electronics

or industrial sensing systems, our infrared LED solutions can be customized to your specific application needs.

For more information, please contact our sales team.

Infrared LED Technology White Paper

Infrared LED Technology White Paper

Industrial LED Selection Guide White Paper

Industrial LED Selection Guide White Paper

LED Plant Spectrum White Paper

LED Plant Spectrum White Paper

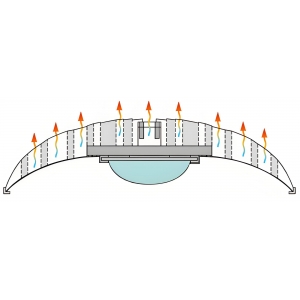

White Paper on High-Power LED Heat Dissipation (2025 Edition

White Paper on High-Power LED Heat Dissipation (2025 Edition

- PRODUCTS

- HIGH POWER WHITE

- HIGH POWER COLOR

- COLOR LEDs

- INFRARED LEDs

- UV LEDs

- MINI LEDs

- COB LEDs

- INTEGRATED MOULES

- MARKETS SERVED

- LIGHTING LEDs

- AUTOMOTIVE LEDs

- BIOMEDICAL LEDs

- DISPLAY LEDs

- CURING DISINFECTION LEDs

- PLANT LEDs

- INFRARED SECURITY LEDs

- VISION LEDs

CONTACT US

TEL:+86-0769-81305858

PH:+8613612789419

E-mail:sales@queendomlamp.com