LED Plant Spectrum White Paper

LED Plant Spectrum White Paper

1. Technical Challenges and Core Demands

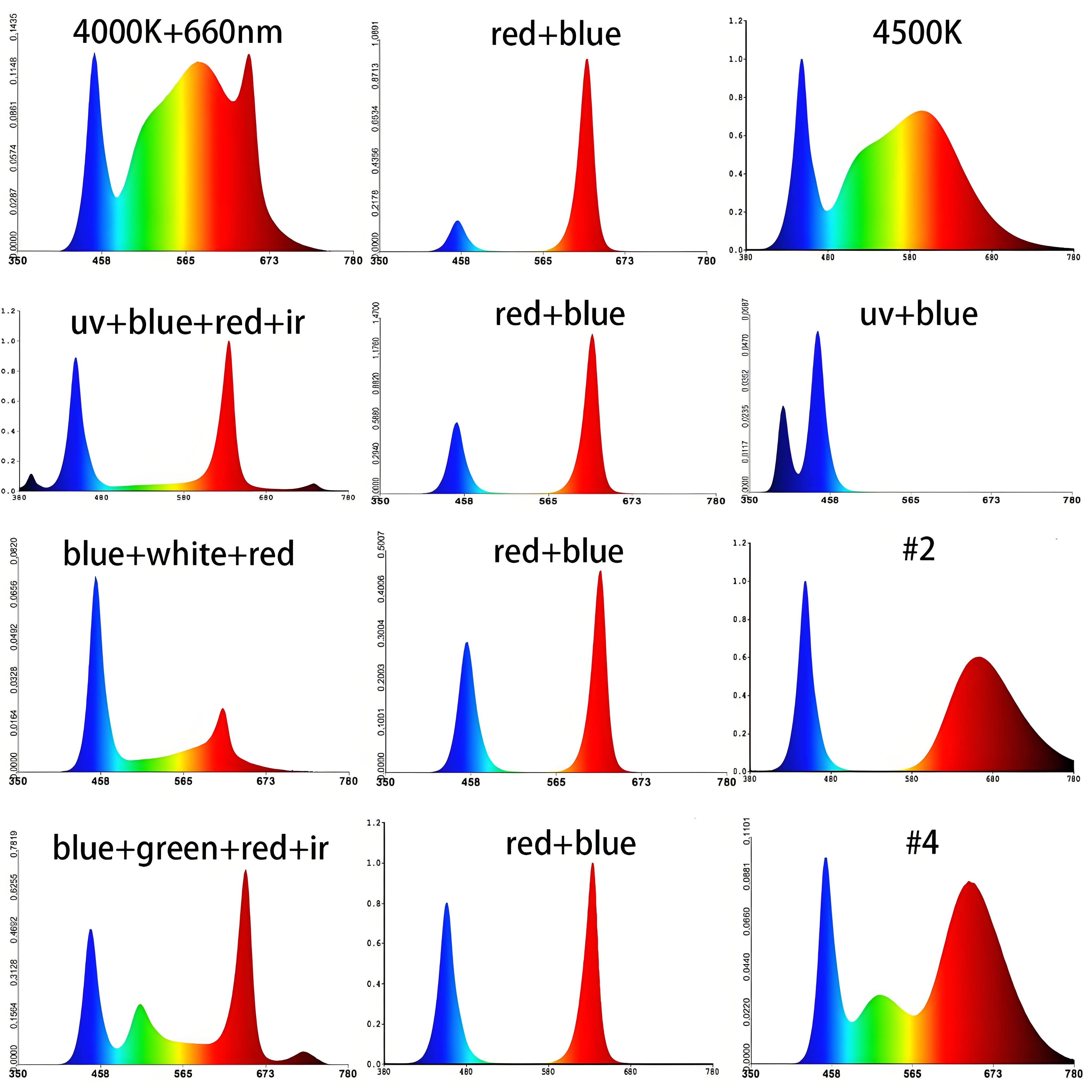

Contradiction between Plant Photophysiological Demands and Spectrum Matching

Plant photosynthesis mainly relies on 400-500nm blue light (chlorophyll a/b absorption peak) and 600-700nm red light (photosensitive pigment

activation zone),

but the spectral matching requirements at different growth stages (seedling/flowering/fruiting) vary significantly.

In traditional LED lighting solutions, 32% of commercial lamps lack the 450nm blue light band, resulting in excessive plant growth or decreased

biomass.

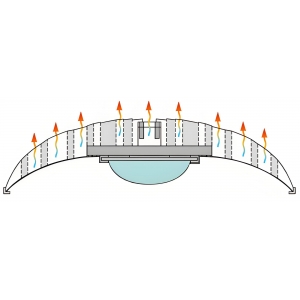

Balance between high light efficiency and energy consumption

Plant factories need to achieve a photon flux density (PPFD) ≥ 800μmol/(m²·s), but the existing white light LED luminous efficiency (PPE) is only 3.3μmol/J,

and heat dissipation and light decay issues are prominent under high power density.

Multi-environment adaptability requirements

Greenhouses, vertical farms and other scenes need to be compatible with moisture-proof, dust-proof (IP65+) and spectral stability, and the light uniformity error must be <15%.

II. Core spectral parameters and design specifications

Spectral ratio standardization

Seedling stage: blue light: red light = 3:7 (blue light promotes root development, red light inhibits excessive growth).

Flowering/fruiting period: Increase 660nm deep red light (activation of phytochrome Pfr) and 730nm far red light (regulation of light cycle).

Photon efficiency and light intensity control

Adopt high PPF (≥0.58μmol/J) LED devices, combined with PWM dimming to achieve 0.2-0.7W power dynamic adjustment, matching the day and night light cycle.

Photon flux density (PPFD) layered control: leaf canopy 800-1200μmol/(m²·s), root supplementary light ≤200μmol/(m²·s).

Optical system optimization

Use secondary optical lenses (such as bat-wing light distribution) to improve light uniformity and reduce edge light attenuation.

Transparent ceramic fluorescent layer technology enhances red light band transmittance (increased by 15%-20%).

III. Technical solutions and industry practices Spectrum customized packaging technology "White light 2835" solution: realize dynamic spectrum

control through

multi-chip integration (3000-7000K color temperature optional), and support phased light formula programming.

Distributed phosphor coating process: solve the problem of local spectrum offset, uniformity error <5%.

Intelligent light environment control system Integrate IoT sensors to monitor PPFD and spectral distribution in real time, and link the fill light system to adjust the

light intensity and band ratio (such as automatically enhancing 660nm red light during flowering).

Hydroponic scene mandatory requirements: fill light intensity ≤ 5000 lux, and automatically turn off the fill light when the water temperature > 28℃.

Low-carbon manufacturing and reliability verification

Lead-free welding process combined with aluminum nitride ceramic substrate (thermal conductivity>170W/(m·K)) ensures 30,000 hours of light decay <5%15.

Spectral stability is verified by accelerated aging test (1000 hours of performance decay <3% under 85℃/85%RH environment).

IV. Future development direction

Full spectrum AI regulation

The AI algorithm based on plant growth model predicts the optimal spectral ratio and realizes dynamic optimization of light formula

(such as automatic enhancement

of 730nm far-red light during tomato color change period).

Cross-domain technology integration

Silicon carbide (SiC) substrate technology improves the output efficiency of the ultraviolet band (380-400nm) and inhibits fungal diseases.

Combining synthetic biology with optogenetics to develop spectrally responsive transgenic crops58. Note: This white paper integrates plant

photophysiology research,

LED packaging technology innovation and large-scale planting practice to provide spectral design and application guidance for scenarios such

as facility agriculture and vertical farms.

Infrared LED Technology White Paper

Infrared LED Technology White Paper

Industrial LED Selection Guide White Paper

Industrial LED Selection Guide White Paper

LED Plant Spectrum White Paper

LED Plant Spectrum White Paper

White Paper on High-Power LED Heat Dissipation (2025 Edition

White Paper on High-Power LED Heat Dissipation (2025 Edition

- PRODUCTS

- HIGH POWER WHITE

- HIGH POWER COLOR

- COLOR LEDs

- INFRARED LEDs

- UV LEDs

- MINI LEDs

- COB LEDs

- INTEGRATED MOULES

- MARKETS SERVED

- LIGHTING LEDs

- AUTOMOTIVE LEDs

- BIOMEDICAL LEDs

- DISPLAY LEDs

- CURING DISINFECTION LEDs

- PLANT LEDs

- INFRARED SECURITY LEDs

- VISION LEDs

CONTACT US

TEL:+86-0769-81305858

PH:+8613612789419

E-mail:sales@queendomlamp.com