White Paper on High-Power LED Heat Dissipation (2025 Edition)

White Paper on High-Power LED Heat Dissipation (2025 Edition)

I. Technical Challenges and Core Demands

Pain Points of Heat Dissipation in High-Power LEDs

Excessive Junction Temperature: If the junction temperature (T<sub>J</sub>) of a 10W-class LED chip is not effectively controlled,

it may cause the light efficiency to decay by more than 50%, and the life span to be shortened to less than 1/3 of the original design.

Heat Dissipation Contradiction in Outdoor Scenarios: High-power outdoor LED lamps need to balance between waterproof and dustproof (IP66/IP68) and

efficient heat dissipation, and the heat dissipation area of traditional aluminum substrates is limited46.

Industry Demand Upgrade

High Power Density: Scenarios such as server power supplies and automotive headlights require LED power density to be increased to more than 500W/cm²,

and the bottleneck of traditional air-cooled heat dissipation needs to be broken through.

II. Core Heat Dissipation Solution

Packaging-Level Optimized Design

Chip Structure: Using flip-chip or vertical chip technology to shorten the heat conduction path and reduce the junction temperature by 15-20℃15.

Substrate material: Aluminum nitride ceramic (AlN) or copper-ceramic composite substrate is preferred, and the thermal conductivity is increased to 200-400W/(m·K),

which is 3-5 times higher than that of traditional aluminum substrates14.

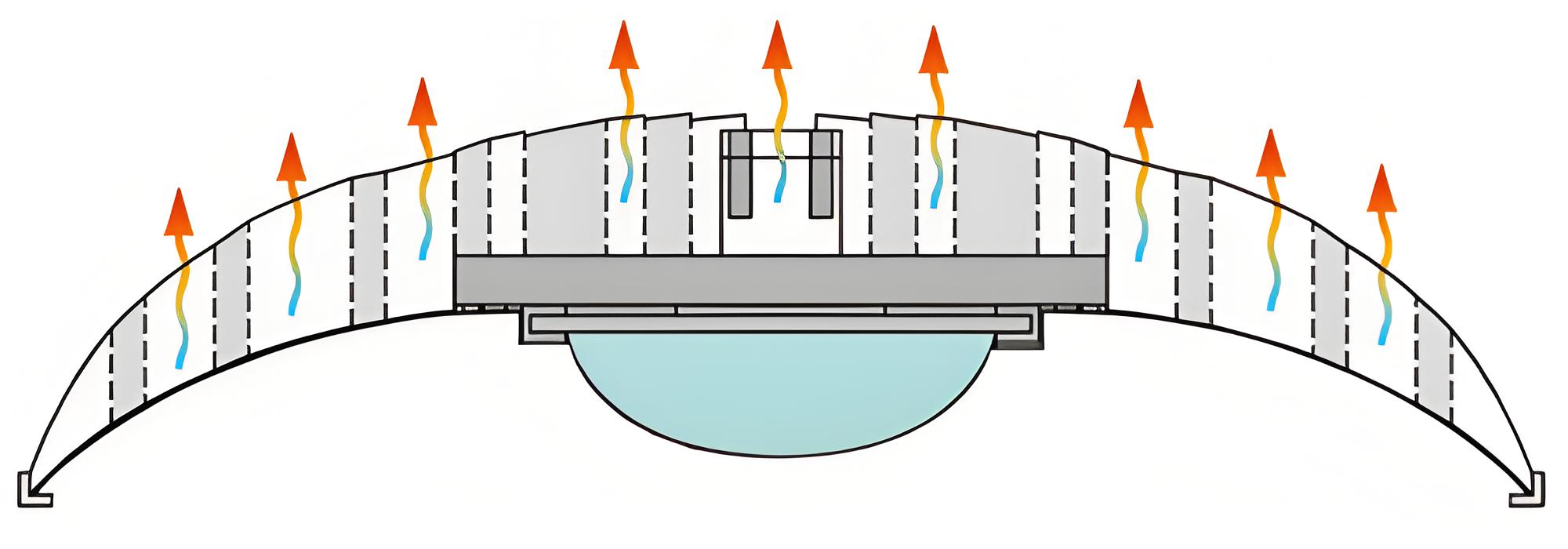

System-level heat dissipation technology

Passive heat dissipation:

Embedded heat pipe design: Integrate ultra-thin heat pipes (thickness ≤3mm) in the LED module to quickly remove heat using phase change cycles36.

All-aluminum integrated die-casting structure: Customize honeycomb heat dissipation fins through CNC process to increase the convection area

by more than 50%

Active heat dissipation:

Microchannel liquid cooling system: Integrated inside the PCB, with a micro pump to drive the coolant circulation, it can carry a power load of more than 1000W.

Material and process innovation

Thermal interface material (TIM): Graphene thermal conductive glue or liquid metal filler replaces traditional silicone grease, and the interface

thermal resistance is

reduced to below 0.1K·cm²/W57.

Environmentally friendly manufacturing: Lead-free welding process combined with low-temperature packaging technology reduces the impact of thermal stress on chip life.

III. Industry practice cases Server power cooling solution Standardized cooling module, using GaN power semiconductors and layered liquid cooling

architecture, so that the temperature rise of 1000W power module is controlled within 30℃, and the efficiency reaches 96%.

Automotive headlight thermal management Layered cooling design: Optimize the LED array layout through CFD simulation, combine aluminum substrate and synthetic

jet technology (SynJet), and achieve temperature uniformity error <3℃.

IV. Future technology direction Intelligent thermal monitoring: Integrate temperature sensors and AI algorithms to dynamically adjust the power consumption of the

cooling system (such as fan speed/liquid cooling flow) to achieve a 20% increase in energy efficiency.

Wide bandgap material application: Silicon carbide (SiC) substrate is combined with gallium nitride (GaN) driver chip to reduce device heat generation and improve

high temperature resistance.

Document Description: This white paper is based on global cutting-edge technology and industrial practice, and is suitable for high-power heat dissipation design in

the fields of LED lighting, automotive electronics, industrial equipment, etc. The full version can be obtained by contacting us.

Infrared LED Technology White Paper

Infrared LED Technology White Paper

Industrial LED Selection Guide White Paper

Industrial LED Selection Guide White Paper

LED Plant Spectrum White Paper

LED Plant Spectrum White Paper

White Paper on High-Power LED Heat Dissipation (2025 Edition

White Paper on High-Power LED Heat Dissipation (2025 Edition

- PRODUCTS

- HIGH POWER WHITE

- HIGH POWER COLOR

- COLOR LEDs

- INFRARED LEDs

- UV LEDs

- MINI LEDs

- COB LEDs

- INTEGRATED MOULES

- MARKETS SERVED

- LIGHTING LEDs

- AUTOMOTIVE LEDs

- BIOMEDICAL LEDs

- DISPLAY LEDs

- CURING DISINFECTION LEDs

- PLANT LEDs

- INFRARED SECURITY LEDs

- VISION LEDs

CONTACT US

TEL:+86-0769-81305858

PH:+8613612789419

E-mail:sales@queendomlamp.com