Industrial LED Selection Guide White Paper

1. Introduction

With the rapid development of LED technology, the demand for LEDs in industrial applications continues to grow. From mechanical equipment lighting to automated inspection systems, LEDs have become a core component in industrial lighting and indication systems. In order to ensure the reliability and efficiency of the system, the correct selection of industrial LEDs is particularly critical.

2. Key performance indicators of industrial-grade LEDs

2.1 Optical performance

Brightness (lumens): Determine the required luminous flux according to the application scenario

Emitting angle: For example, narrow angle (<30°) is used for focusing, and wide angle (>120°) is used for floodlighting

Color rendering index (CRI): It is recommended to use CRI > 80 in industrial lighting situations

2.2 Electrical characteristics

Forward voltage (VF) and current (IF) matching: Ensure stable operation of LEDs

Power consumption control: Low power consumption design helps system energy saving and thermal management

ESD protection capability: LEDs with high anti-static ability should be selected in industrial environments

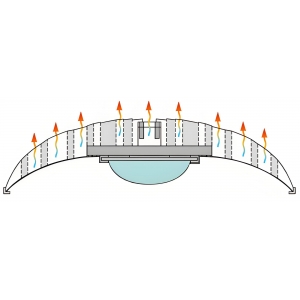

2.3 Thermal performance

Thermal resistance parameters (RθJA/RθJC): The lower the thermal resistance, the better the heat dissipation

Packaging form: For example, ceramic packaging is better than plastic packaging and is suitable for high temperature environments

2.4 Environmental adaptability

Operating temperature range: Industrial LEDs usually require -40℃ to +85℃ or even wider

Protection level (IP level): If dust and water resistance are required, IP65 or above should be selected

3. Common application scenarios and selection suggestions

Application areas

Recommended wavelength/color temperature

Key features

Mechanical lighting

5000-6500K cold white light

High brightness, vibration resistance

Signal indication

Red, green, yellow light

Quick response, high color purity

Detection lighting

High CRI white light, ultraviolet

High color rendering, stable light output

Outdoor equipment

4000-5500K

High protection level, wide temperature operation

4. Selection process suggestions

Clear application environment and requirements (temperature, humidity, vibration, electromagnetic interference, etc.)

Determine the required spectral characteristics and brightness level

Select LED products that meet electrical parameters and thermal management requirements

Audit certification standards (RoHS, CE, UL, etc.)

Small batch testing and verification before batch import

5. Trends

Higher integration packaging: COB, MCOB and other efficient packaging technologies

Intelligent control interface: support PWM, I2C and other intelligent dimming

Green environmentally friendly materials: meet higher environmental protection and recyclable standards

6. Conclusion

The correct selection of industrial-grade LEDs is the basis for ensuring reliable operation of equipment. By comprehensively considering factors such as optical, electrical, thermal performance and environmental adaptability, efficient and durable lighting and indication solutions can be provided for various industrial applications.

Infrared LED Technology White Paper

Infrared LED Technology White Paper

Industrial LED Selection Guide White Paper

Industrial LED Selection Guide White Paper

LED Plant Spectrum White Paper

LED Plant Spectrum White Paper

White Paper on High-Power LED Heat Dissipation (2025 Edition

White Paper on High-Power LED Heat Dissipation (2025 Edition

- PRODUCTS

- HIGH POWER WHITE

- HIGH POWER COLOR

- COLOR LEDs

- INFRARED LEDs

- UV LEDs

- MINI LEDs

- COB LEDs

- INTEGRATED MOULES

- MARKETS SERVED

- LIGHTING LEDs

- AUTOMOTIVE LEDs

- BIOMEDICAL LEDs

- DISPLAY LEDs

- CURING DISINFECTION LEDs

- PLANT LEDs

- INFRARED SECURITY LEDs

- VISION LEDs

CONTACT US

TEL:+86-0769-81305858

PH:+8613612789419

E-mail:sales@queendomlamp.com