LED spectral technology for plant factories

LED spectral technology for plant factories

I. Core technology architecture

Spectrum customization design

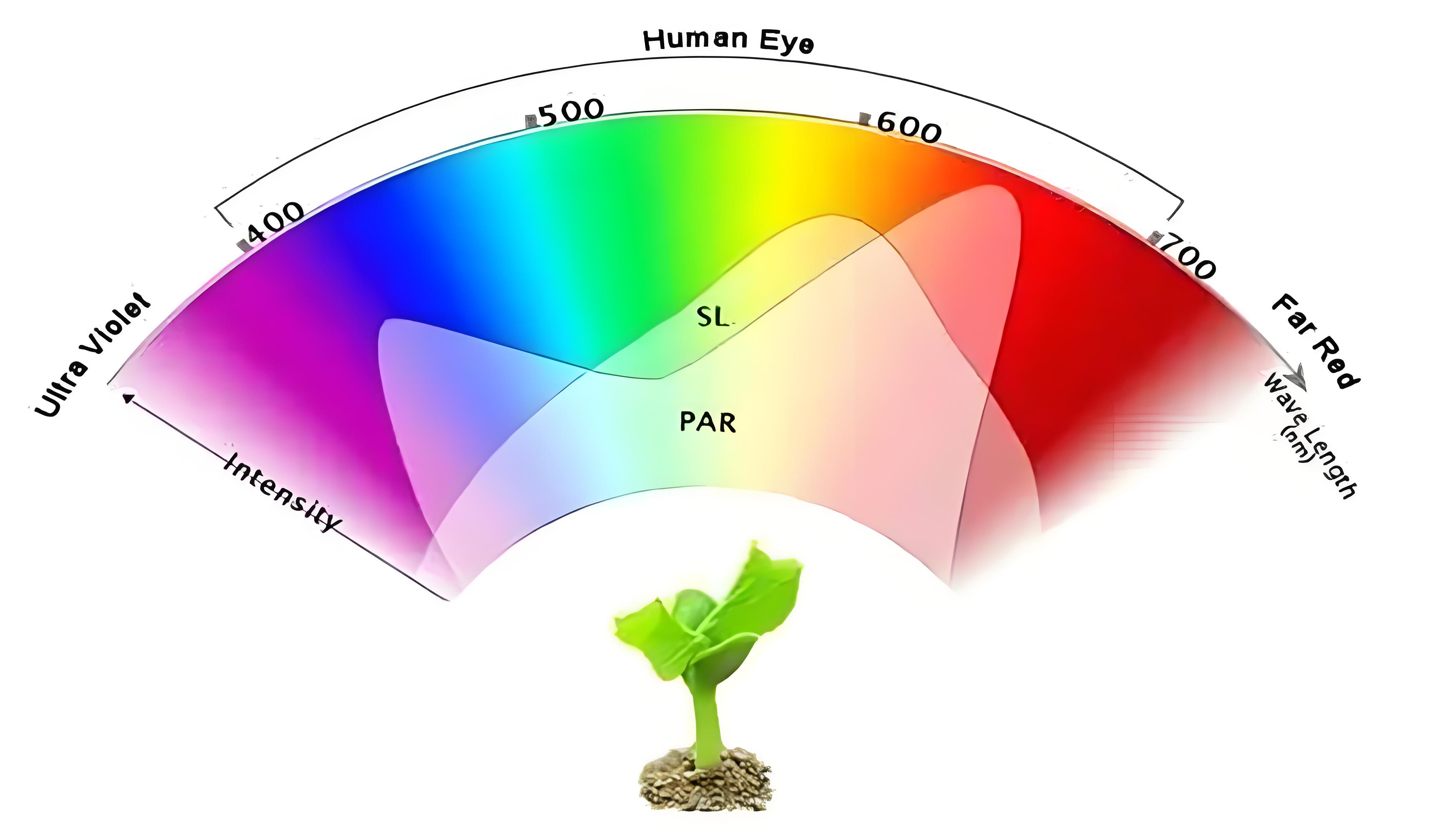

The spectrum of LED plant lights needs to be customized based on the planting process, rather than imitating a general solution. It needs to cover the key bands

of photosynthesis (400-720nm) and match the needs of the plant growth stage.

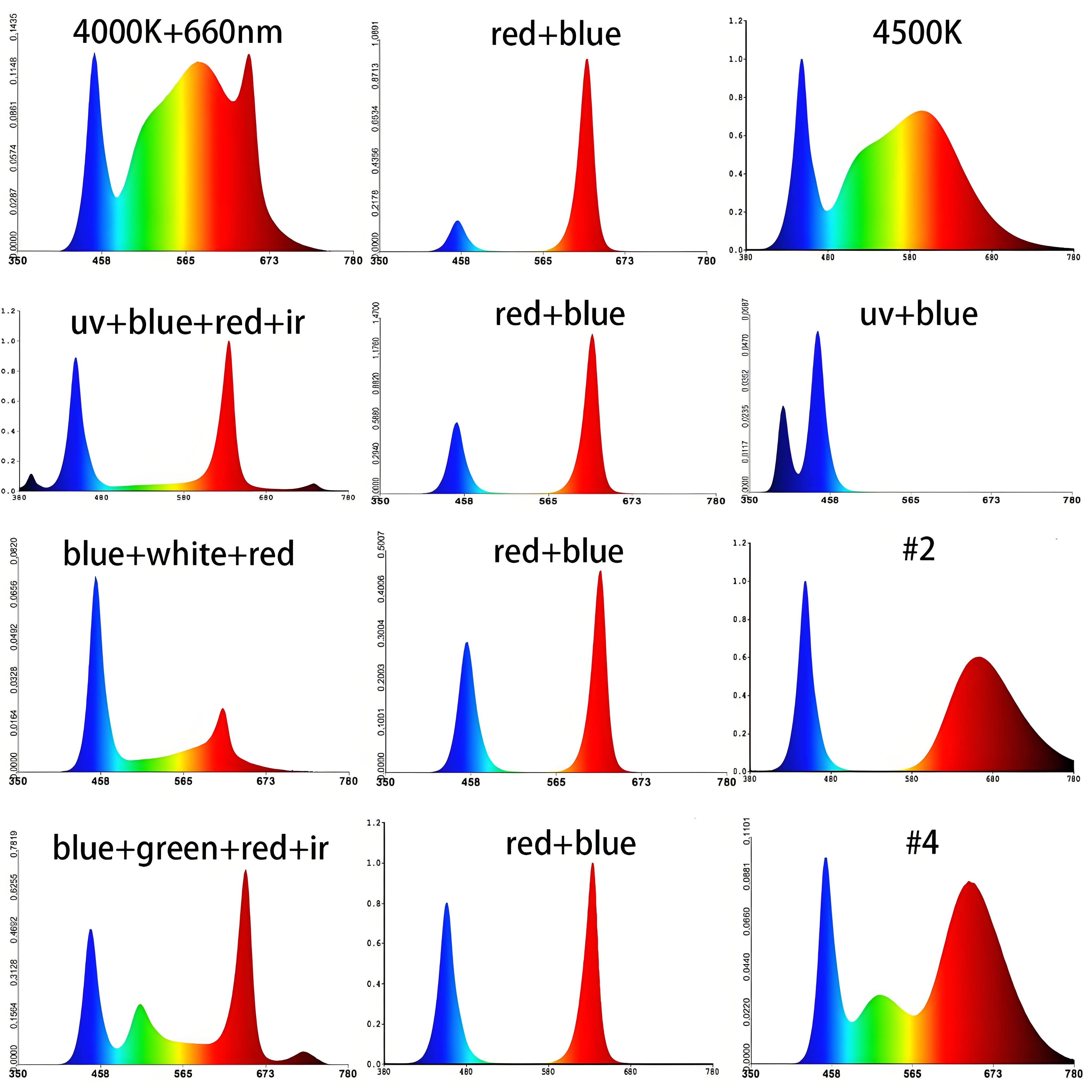

Mainstream solutions include:

Monochromatic light combination: 450nm blue light (chlorophyll absorption peak), 660nm red light (photosensitive pigment activation), and 730nm far-red light

(photoperiod regulation) as the core bands.

Full spectrum coverage: Through the superposition of white light LED and red light reinforcement, a low-cost universal solution is achieved.

Dynamic spectrum regulation capability

Integrated intelligent dimming system supports real-time adjustment of the red and blue light ratio according to the plant growth stage (seedling/flowering/fruiting)

(such as 30%-40% blue light in the seedling stage)

Using PWM dimming technology, the photon flux density (PPFD) is precisely controlled within the range of 200-800μmol/(m²·s) to match the diurnal photoperiod and

environmental changes.

Layered management of light formula

Leaf canopy: high light intensity (PPFD ≥ 800μmol/(m²·s)) with 660nm red light dominant spectrum to promote photosynthetic rate.

Root supplementary light: low intensity (≤200μmol/(m²·s)) blue light assists to inhibit excessive growth and enhance root development.

2. Application of key technologies

Spectrum matching with plant physiological responses

Blue light (450-470nm) regulates stomatal opening and chlorophyll synthesis, and red light (660nm) activates photosensitive pigment Pfr to accelerate flowering and

fruit ripening.

Far red light (730nm) promotes light morphology through photoperiod regulation, shortening the growth cycle by more than 20%.

Optical system optimization

Bat-wing lens is used to improve light uniformity (error <15%) and reduce edge light attenuation .

Transparent ceramic fluorescent layer technology enhances red light transmittance (+15%-20%) and reduces light decay risk .

Multi-environment adaptability solution

Silicon carbide substrate is used in high temperature and high humidity scenes (such as tropical plant factories) to ensure light decay <5% in 85°C environment .

IP66 protection design is compatible with hydroponic system to prevent moisture erosion .

3. Future technology direction

AI-driven dynamic spectrum

The AI algorithm based on plant growth model optimizes light formula in real time, such as automatically enhancing the proportion of 730nm far-red light during the

color change period .

Ultraviolet band integration

Develop 380-400nm ultraviolet LED modules to inhibit fungal diseases and increase the content of secondary metabolites (such as medicinal plants) .

Interdisciplinary integration and innovation

Optogenetics technology is used to cultivate spectrally responsive crops and reduce dependence on artificial supplementary lighting . The combination of gallium nitride

(GaN) driver chips and liquid cooling can improve system energy efficiency by 30%.

Note: LED spectrum technology in plant factories needs to deeply integrate photobiology, material science and intelligent control, with precise light formula as the core to

achieve high crop yield, high quality and energy saving goals.

LED spectral technology for plant factories

LED spectral technology for plant factories

LED spectrum design for greenhouse plant growth

LED spectrum design for greenhouse plant growth

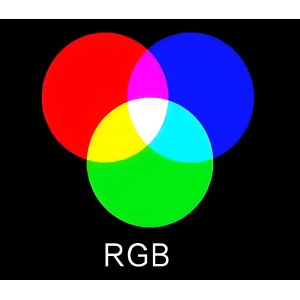

What is the difference between RGBW and RGB?

What is the difference between RGBW and RGB?

- PRODUCTS

- HIGH POWER WHITE

- HIGH POWER COLOR

- COLOR LEDs

- INFRARED LEDs

- UV LEDs

- MINI LEDs

- COB LEDs

- INTEGRATED MOULES

- MARKETS SERVED

- LIGHTING LEDs

- AUTOMOTIVE LEDs

- BIOMEDICAL LEDs

- DISPLAY LEDs

- CURING DISINFECTION LEDs

- PLANT LEDs

- INFRARED SECURITY LEDs

- VISION LEDs

CONTACT US

TEL:+86-0769-81305858

PH:+8613612789419

E-mail:sales@queendomlamp.com