Thermal Management Basics

Thermal Management Basics

Heat dissipation is not an option, but a necessity.

High-power LEDs generate much more heat than ordinary light sources. If the heat cannot be removed in time, the following risks will occur:

The chip junction temperature rises, resulting in a decrease in luminous flux

The light decay accelerates and the life is reduced sharply

Solder point fatigue and structural deformation eventually lead to failure

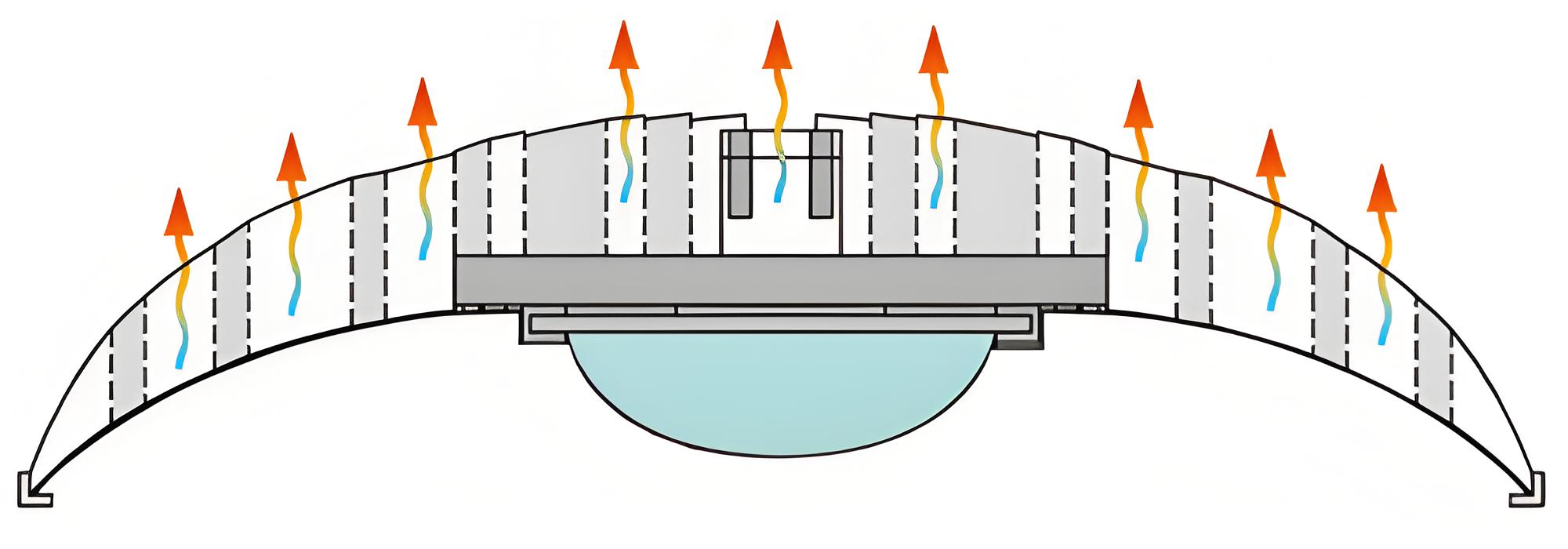

Three elements of heat dissipation structure:

Heat conduction (chip → substrate)

Aluminum substrate and ceramic substrate are recommended

High thermal conductivity solder or silver glue is used between the chip and the substrate

Heat transfer (substrate → radiator)

Use thermal grease or thermal pad to fill the gap

Screw compression installation to ensure that there is no thermal resistance gap

Heat dissipation (radiator → air)

Aluminum profile radiator (anodized is better)

Natural convection or active air cooling combination

The housing needs to be designed with ventilation holes/heat dissipation channels

Recommended heat dissipation area reference table:

Power level Recommended heat dissipation area Heat dissipation method

≤ 5W ≥ 50 cm² Natural convection

5~15W ≥ 120 cm² Natural convection + thermal pad

≥ 20W ≥ 250 cm² Forced air cooling/heat pipe module

Design suggestions:

Avoid heat accumulation in closed structures

Do not stack heating components (such as driver power) under LED modules

NTC thermistor can be embedded to implement over-temperature protection logic

Thermal Management Basics

Thermal Management Basics

- PRODUCTS

- HIGH POWER WHITE

- HIGH POWER COLOR

- COLOR LEDs

- INFRARED LEDs

- UV LEDs

- MINI LEDs

- COB LEDs

- INTEGRATED MOULES

- MARKETS SERVED

- LIGHTING LEDs

- AUTOMOTIVE LEDs

- BIOMEDICAL LEDs

- DISPLAY LEDs

- CURING DISINFECTION LEDs

- PLANT LEDs

- INFRARED SECURITY LEDs

- VISION LEDs

CONTACT US

TEL:+86-0769-81305858

PH:+8613612789419

E-mail:sales@queendomlamp.com