Application and Technology of UV LEDs in Medical Treatment

Application and Technology of UV LEDs in Medical Treatment

1. Market Background of UV LED Medical Disinfection

In recent years, the global demand for medical infection prevention and control has surged, and traditional chemical disinfection methods (such as alcohol and

chlorine-containing disinfectants) have problems such as corrosiveness, residues and drug resistance. UV-C (ultraviolet C band, 200-280nm) has become an

emerging solution for medical disinfection due to its high efficiency in sterilization (destroying microbial DNA/RNA) and no chemical residue.

Market data:

According to Market Research Future, the global UV LED disinfection market will have an annual compound growth rate (CAGR) of 18.5% from 2023 to 2030,

with the medical field accounting for more than 40%.

The COVID-19 epidemic has accelerated the application of UV LED in the disinfection of operating rooms, ICUs, and medical devices.

2. Core advantages of UV LED in medical disinfection

Compared with traditional mercury lamp UV technology, UV LED has the following advantages:

Comparison dimensions UV LED Traditional mercury lamp UV

Sterilization efficiency 265-275nm peak wavelength, sterilization rate>99.9% 254nm wavelength, some microorganisms are resistant

Energy consumption and life Low power consumption (energy saving 50%+), life 10,000 hours+ High power consumption, life only 1,000-3,000 hours

Environmental protection No mercury pollution, compliant with RoHS standards Contains mercury, requires special recycling treatment

Instant switch Start in seconds, no preheating required Preheating takes 5-10 minutes

Miniaturization of equipment Can be integrated into portable devices (such as handheld disinfection devices) Large size, inconvenient to move

3. Typical application scenarios in the medical field

(1) Air and surface disinfection

Operating room/ICU disinfection: UV LED modules are embedded in the air conditioning system or ceiling lights to achieve continuous air purification.

High-frequency contact surfaces (such as door handles and bed rails): The robot is equipped with a UV LED array for automatic cruise disinfection.

Case: The UV LED disinfection robot developed by Xenex, a US company, can kill MRSA (methicillin-resistant Staphylococcus aureus) within 5 minutes.

(2) Sterilization of medical devices

Reusable instruments such as endoscopes and catheters: UV LED assembly line equipment replaces ethylene oxide (EtO) chemical sterilization to avoid carcinogenic

residues.

Packaging of disposable medical supplies: UV LED online irradiation to ensure sterile packaging.

(3) Water treatment and blood product safety

Hospital water supply system: UV LED kills drug-resistant pathogens such as Legionella and Cryptosporidium.

Plasma/vaccine production: Used for inactivation of pathogens in biological products to avoid damage to heat-sensitive components.

4. Technical challenges and breakthrough directions

(1) Power and wavelength optimization

Challenges: High-power UV LEDs (>100mW) still have heat dissipation and light decay problems.

Breakthrough:

AlGaN (aluminum gallium nitride) materials improve external quantum efficiency (EQE).

Microfluidic cooling technology solves the heat dissipation bottleneck.

(2) Intelligent control system

Dynamic adjustment: Automatically adjust the UV dose according to the environmental microbial load (such as Siemens' UV-C sensing system).

Safety protection: Infrared sensors ensure that it is activated in an unmanned environment to avoid human exposure.

(3) Cost and standardization

Current situation: The unit price of UV LED is still higher than that of mercury lamps, but the long-term comprehensive cost is lower.

Trend: Large-scale production (such as Seoul Semiconductor and Nichia's expansion) drives prices down.

5. Future trend outlook

Popularization of portable devices: Growth of personal protection products such as UV LED flashlights and mask disinfection boxes.

Integration with AI/IoT: Hospitals monitor the disinfection effect in real time through the Internet of Things (IoT).

Policy drive: Countries gradually phase out mercury-containing UV lamps (such as the EU Minamata Convention), and UV LED substitution is accelerated.

Conclusion

UV LED is reshaping the medical disinfection industry with its high efficiency, safety and environmental protection. As the technology matures and costs decrease,

its application will extend from hospitals to homes, public transportation and other scenarios, becoming one of the core technologies for infection prevention and control in the post-epidemic era.

(If you need specific product solutions or technical parameters, please contact: sales@queendomlamp.com)

Military-Grade IR Technology Now Available for Commercial Us

Military-Grade IR Technology Now Available for Commercial Us

Application and Technology of UV LEDs in Medical Treatment

Application and Technology of UV LEDs in Medical Treatment

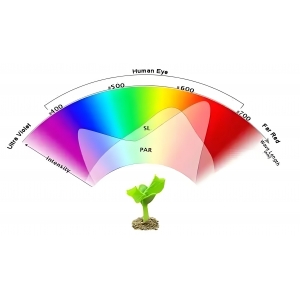

LED spectrum design for greenhouse plant growth

LED spectrum design for greenhouse plant growth

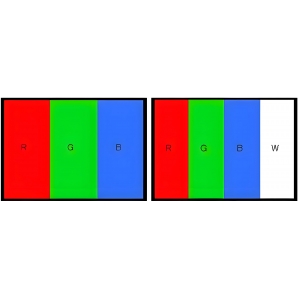

What is the difference between RGBW and RGB?

What is the difference between RGBW and RGB?

- PRODUCTS

- HIGH POWER WHITE

- HIGH POWER COLOR

- COLOR LEDs

- INFRARED LEDs

- UV LEDs

- MINI LEDs

- COB LEDs

- INTEGRATED MOULES

- MARKETS SERVED

- LIGHTING LEDs

- AUTOMOTIVE LEDs

- BIOMEDICAL LEDs

- DISPLAY LEDs

- CURING DISINFECTION LEDs

- PLANT LEDs

- INFRARED SECURITY LEDs

- VISION LEDs

CONTACT US

TEL:+86-0769-81305858

PH:+8613612789419

E-mail:sales@queendomlamp.com