QUALITY

The company strictly follows the requirements of the ISO/TS16949 quality management system, is guided by "meeting customer needs",

uses five core tool manuals, and uses quality policy, quality objectives, supervision and audit, and data analysis to continuously improve and verify the effectiveness

of the quality management system.

Statement on conflict minerals

"Conflict minerals" refer to gold, tantalum, tungsten, and tin minerals that originate in its neighboring countries. The sale of these minerals may provide financial support

for the ongoing armed conflicts in these countries. Celebrity House has always adhered to the social responsibility of the supply chain as an important part of realizing corporate value,

attaches great importance to conflict minerals, and is committed to working with customers and suppliers to find sustainable solutions to deal with conflict minerals. Here,

we solemnly declare and promise not to purchase or support the use of conflict minerals. At the same time, we also require our suppliers to:

(1) Ensure that all products do not use conflict minerals, and we will stop all business for suppliers that violate

(2) Ensure that products containing gold, tantalum, tungsten or tin (referred to as applicable products) can only be purchased from smelters certified by CFSI

(3) Trace the source of gold, tantalum, tin and tungsten contained in the applicable products, and cooperate in filling out and submitting the CMRT survey form

(4) Extend this requirement to the next-tier suppliers

Quality management system

"Quality Management System-Organization and Implementation of ISO9001: 2000 Special Requirements for Production Parts and Related Service Parts in the Smart Home Industry"

is a technical specification for the smart home industry, based on ISO9001 and added to the technical specifications for the smart home industry.

This specification is completely consistent with ISO9000, but focuses more on defect prevention and reducing quality fluctuations and waste that are prone to occur in the smart

home parts supply chain. The company passed the ISO/TS16949 certification in 2007 and obtained the authorized certificate. In 2013, it passed the supervision audit and

obtained the renewal.

District Mayor Quality Award

Always insist on putting independent innovation, excellent quality and long-term benefits at the top of development. In 2017, the company won the excellent quality brand.

The 2018 District Mayor Quality Award is the highest quality award. It is awarded for outstanding achievements in quality management and operational performance, product,

service, engineering quality, environmental protection and pollution control level, independent innovation ability and market Competitiveness and other comprehensive

operation management are in a leading position at home and abroad, have a significant industry demonstration and lead role, and make outstanding contributions to the

economic and social development of the region.

Environmental commitment

"To achieve energy conservation and environmental protection with science and technology, and to build a green home with innovation and hard work", "

consume one kilowatt-hour of electricity and restore one more green" is the company's corporate mission. The company has always persisted in the development and

popularization of energy-saving technology, and strives to make unremitting efforts to drive the butterfly effect of energy-saving and environmental protection,

and make outstanding contributions to the global green environmental protection cause. The company's products meet the current international environmental

protection RoHS, REACH, PFOS/PFOA and other laws and regulations, and related products have passed the IEC62471 photobiological safety test requirements.

The company leads by example in scientific research, production, management, and daily life, saving energy consumption, reducing material waste, controlling waste discharge, etc.,

to achieve energy conservation commitments.

Quality Control

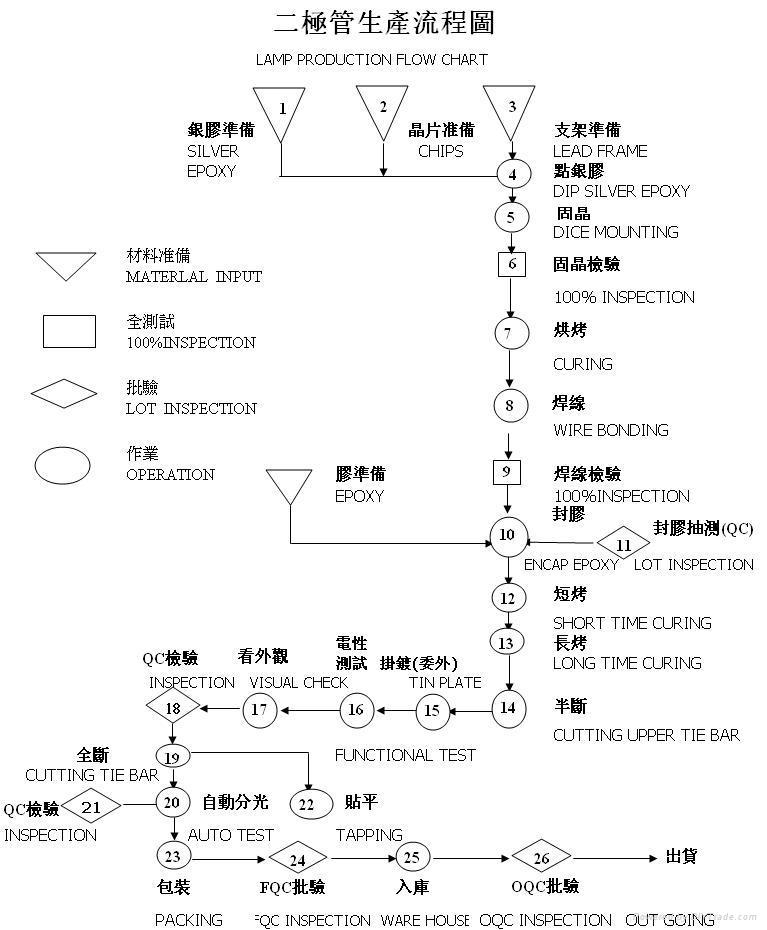

1. Methods, technical routes and processes used

01 High CRI and long life

Through the principle of electrochemistry, the LED dead light and leakage are strengthened, and then the packaging manufacturing is increased to increase the weldable tensile force,

increase the temperature resistance of the glue, and further improve the product performance.

02 Automated production equipment

In order to ensure product consistency, from raw materials directly to finished products, a complete set of automated equipment is independently developed; improve production efficiency.

03 Precision type

High standard unified specification 2.5nm, white light refinement standard warm white 30-50K/PIN; neutral color temperature 100-150K; VF: 0.1v/PIN, 100% automated appearance electrical

detection.

2. LED light source is an important part of lighting. Poor quality light source can easily lead to dead light of lighting products. All products are self-packaged, independent workshops,

equipped with advanced high-speed packaging and testing equipment to ensure accuracy and consistency.

3. Poor quality materials have uneven cuts, different lengths, bursts, and cause welding problems, resulting in defective products. Zhengfa Technology solves these problems from the source,

controlling the cutting, molding, and quality inspection of LED chips, and is equipped with detection tubes to ensure that the tube body is intact and beautiful, the incision is complete

and smooth, and the length is consistent.

Process Control Verification

Our Promise

Quality is not a slogan—it’s a system.

We are committed to delivering reliable, consistent, and high-performance LED components for customers worldwide. With Queendom, you can count on a trusted partner that

delivers both innovation and dependability.

From prototypes to full-scale production—our LEDs are engineered to exceed expectations.

- PRODUCTS

- HIGH POWER WHITE

- HIGH POWER COLOR

- COLOR LEDs

- INFRARED LEDs

- UV LEDs

- MINI LEDs

- COB LEDs

- INTEGRATED MOULES

- MARKETS SERVED

- LIGHTING LEDs

- AUTOMOTIVE LEDs

- BIOMEDICAL LEDs

- DISPLAY LEDs

- CURING DISINFECTION LEDs

- PLANT LEDs

- INFRARED SECURITY LEDs

- VISION LEDs

CONTACT US

TEL:+86-0769-81305858

PH:+8613612789419

E-mail:sales@queendomlamp.com